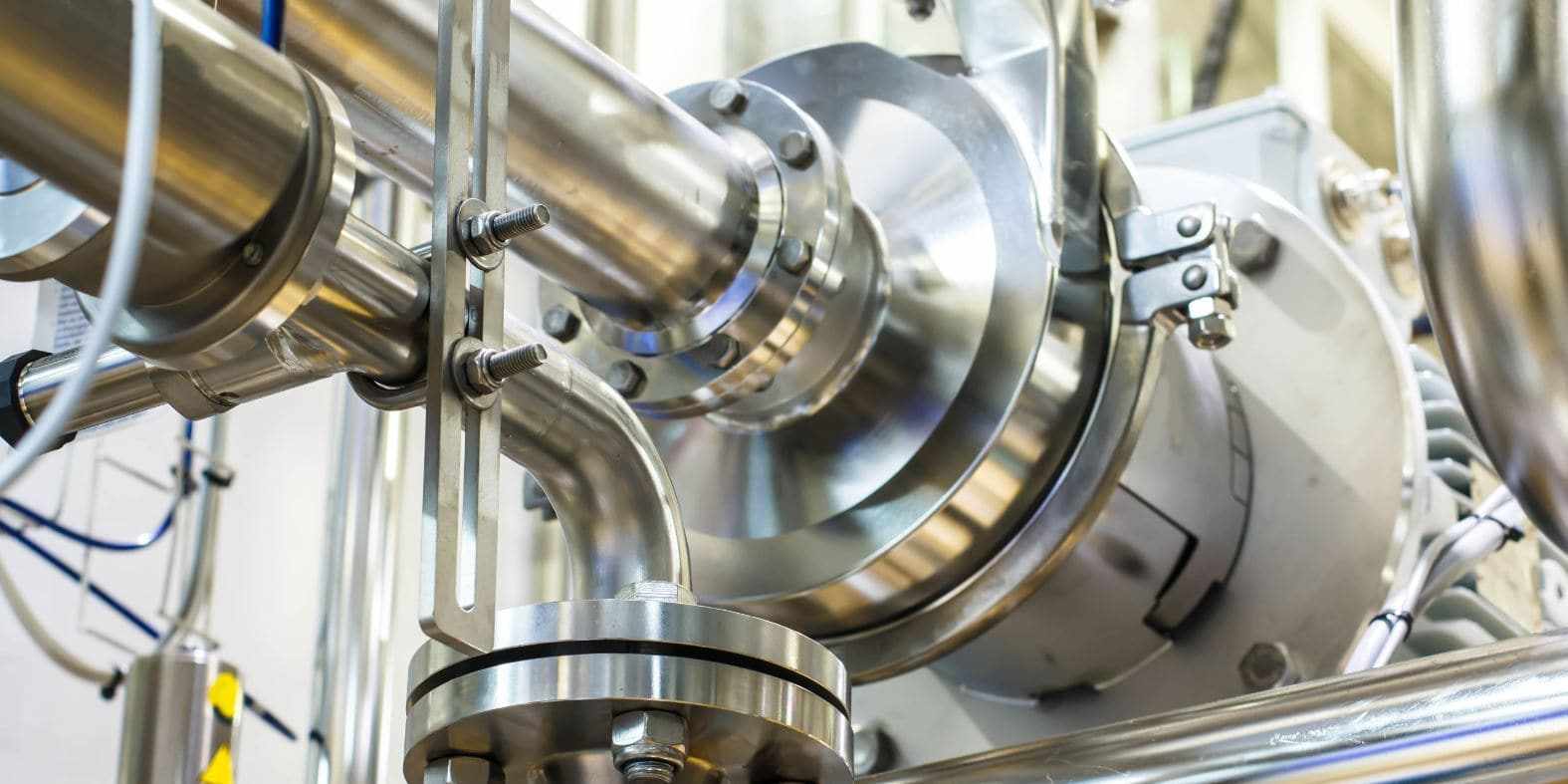

In the desert-climate industries of the UAE, heavy plant equipment endures punishing conditions: high heat, abrasive dust, corrosive humidity, and rigorous duty cycles. One UAE-based firm faced repeated issues with early wear, corrosion and downtime across stainless steel piping, valves and rotating assemblies. Their breakthrough came when they adopted a three-phase surface-treatment and lubrication programme: pickling and passivation, followed by targeted lubrication—to systematically extend the equipment’s service life.

Phase 1 – Pickling & Passivation to reset surface integrity

First they applied a trusted chemical regimen of pickling and passivation to all key stainless steel components. Pickling removes mill scale, heat-tint, welding oxides and other contaminants that compromise the inherent corrosion resistance of the metal. Following that, passivation restores or builds the protective chromium-oxide passive film on stainless steel surfaces—this film is critical because without it the steel becomes susceptible to corrosion and pitting.

In the UAE plant case, the company selected a local chemical partner and used a pre-commissioning approach. They started by degreasing internal pipelines, then circulated acid-based pickling baths on critical assemblies, rinsed thoroughly, neutralised, then applied a citric/nitric-based passivation treatment. The standard helps ensure elimination of free iron, restoration of passive film and proper surface conditioning.

By doing that, they removed hidden corrosion-initiating defects, cleaned internal bore surfaces and ensured that each component started at a “known baseline” of cleanliness and metal integrity.

Phase 2 – Lubrication to protect moving parts and component interfaces

With surfaces cleaned and passivated, the next part was ongoing lubrication of rotating, sliding or sealing elements—especially in gearboxes, bearings, flanged joints and pump assemblies. As many “lubricant companies in UAE” highlight, proper lubrication can dramatically extend equipment life by reducing friction, wear, heat build-up and contamination risk.

In practice the company introduced a lubrication-regime that included:

Selection of high-quality synthetic oils and greases suitable for Gulf temperatures (>45 °C) and dusty environments.

Scheduled oil/grease analyses and condition monitoring to ensure lubricant integrity and no hidden wear.

Application of automatic or centralised lubrication delivery in hard-to-reach or continuous-duty components to avoid manual-error and intermittent lubrication.

By integrating lubrication right after surface treatment, the company protected the cleaned surfaces, avoided new abrasion or corrosion from sliding contact, and thereby maximised service life of moving parts.

Phase 3 – Synergy: Surface treatment + lubrication equals extended service

The real gains came from combining the two regimes. Here’s how the synergy worked:

After pickling and passivation, components had optimum corrosion and contamination resistance. This clean state meant that lubrication could perform optimally—no hidden oxides or scale to disrupt lubricant film.

Lubrication then maintained that state by protecting interfaces, reducing wear and preventing build-up of damaging deposits or particles.

Over time, the company recorded fewer unscheduled shutdowns, fewer bearing failures, reduced corrosion-related leaks and flange failures, and overall lower maintenance cost.

The total equipment lifespan extended significantly—not just based on anecdote but supported by wear-data: companies that follow combined surface engineering + lubrication programmes report life extension of up to 30-50 %.

Practical takeaways for other companies in the UAE

If your organisation is facing premature wear, corrosion or frequent equipment replacement, here are some actionable lessons:

Treat critical components early – before major issues arise, schedule pickling and passivation on welds, pipes, tanks and assemblies particularly exposed to harsh conditions.

Choose lubricants for the environment – Gulf conditions demand high-temp resistance, dust resistance and chemical-resistance lubricants. Work only with reputable “lubricant companies in UAE” that understand local conditions.

Link surface treatment to lubrication – surface engineering is no longer separate from lubrication; treat surfaces then protect moving parts with the right lubrication.

Monitor and maintain – schedule oil/grease analyses, check passive film integrity, and keep records. That helps you catch degradation early and avoid costly replacements.

Partner with a reliable supplier – The company in this case worked closely with their chemical service partner and their lubricant supplier to create an integrated maintenance schedule—and you should too.

Don’t let equipment become a recurring cost centre. Take the proactive step now: contact our team at Al Taher Chemicals to explore how a tailored combination of pickling and passivation plus a robust lubrication programme can protect your assets, enhance uptime and extend service life. Get in touch today and safeguard your investment.

Write a comment ...